Wide range of capabilities

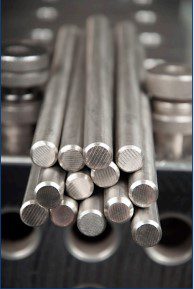

In working with exotic materials and high temperature alloys, SOR has significant and broad experience in terms of machining and welding these different types of materials. SOR works with these materials on a daily basis and has supplied thousands of our standard products with variations in material including exotics and high temperature alloys.

A variety of exotic materials to choose from

SOR has a strong commitment to deliver engineered solutions for standard products. We maintain an inventory of both exotic and well-known materials in house to suit a variety of customer application requirements. SOR has a long history of using exotic materials on pressure ports and parts for the chamber pressure boundary.

• Incoloy 800

• Incoloy 825

• Haynes HR160

• Haynes 230

• Hastelloy B2

• Hastelloy B3

• Hastelloy C22

• Hastelloy X

• Hastelloy C276

• F9

• F11

• F22

• F91

• Nickel 200

• Monel 400

• Inconel 600

• Carpenter 20

• Carbon Steel

• 304 Stainless

• 304H Stainless

• 304L Stainless

• 310 Stainless

• 316 Stainless

• 316H Stainless

• 316L Stainless

• 317 Stainless

• 317L Stainless

• 321 Stainless

• 347 Stainless

• 446 Stainless

• Duplex 2205

• F51 Super Duplex

• F5

We manage the entire process

SOR can handle stringent requirements from many large companies that have standards for piping, NDE, welding, material traceability, corrosion allowance and testing, and inspections. We start by ordering parts from quality suppliers that can provide traceability all the way back to the mill/foundry. This traceability follows the material along the entire process at SOR. Our systems will manage against heat codes, with Mill Test Reports (MTR) for all the material listed in the product. Detailed inspections are performed on the parts at receiving. These inspections look at the certificates based upon a wide variety of chemical and mechanical properties for the material such as: chemical composition, yield and tensile strength, and hardness. All chamber pressure boundary material coming into SOR facilities must conform to an ASTM standard. After incoming inspection, the material is properly segregated for a specific job in order to keep traceability. In addition, the paperwork for the material flows with the job in a documentation traveler package that is stored with the material and inside our

business system.