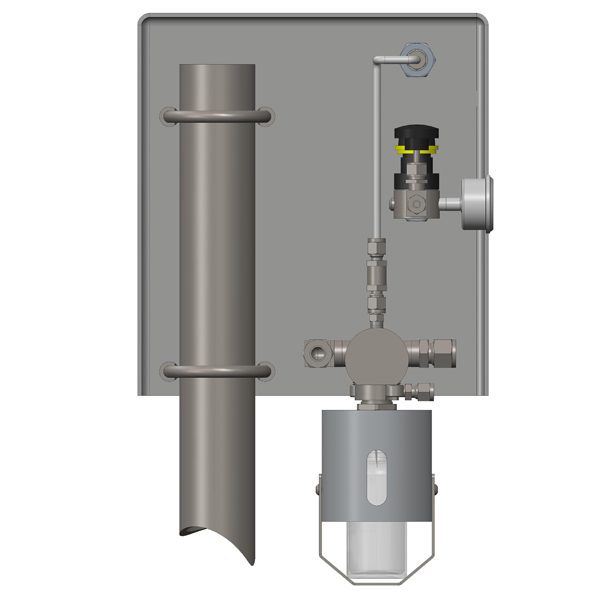

Basic Bottle Sampling Systems

Models: BBSS

Warranty: 1 Year

Simple, flow-thru valve design ideal for fast loop

Zero dead volume

Replaceable process and vent needles

Available with SENSOR Needle Evacuation System for residual elimination and zero emission

Zero emissions/captured vent

The SENSOR Basic Bottle Sampling System (BBSS), is a closed loop liquid grab sample system that is ideal for processes with pressure less than 150 psig and process temperature less than 135ºF. The sample is dispensed into the sample bottle by merely turning a valve. Process pressure forces the sample through the valve into the bottle. With SENSOR Needle Evacuation System (NES), zero dead volume is ensured throughout the sample valve assembly by forcing out any vapor locked liquid.

- Suitable for a wide range of process pressures and temperatures where uninterrupted “fast loop” flow is desired

- Ideal for all hazardous, low vapor pressure liquids

- Well suited for acids, caustics and chemicals where 02 or H2O exposure may deteriorate the sample

- Incorporates a unique needle valve design that virtually guarantees the stem will never seize due to process build up

- Independently replaceable process needle and solid point vent needle

- No dead volume when used in conjunction with Needle Evacuation System (NES)

- Utilizes a solid point vent needle that assures the vent will not plug

- Replaceable/interchangeable needle adapter

- Sample valve stem threads are above the packing to eliminate galling

- Adjustable shroud with viewing window protects operator in the event of a ruptured bottle

- 316L wetted parts standard

- 316L metal seat with floating ceramic ball stem tip

- Standard shroud sizes are 2 oz. to 32 oz. (60mL – 1000mL), other sizes available upon request

- Operating instructions and safety tags are mounted on plate

- Operating Instruction Manual included with each system

Be sure and look at the other sampling system models that are available like the Cylinder Sampling Systems.

Datasheet

Ready to find out more?

Drop us a line today for a free quote!

805QS Pressure Switch-Transmitter

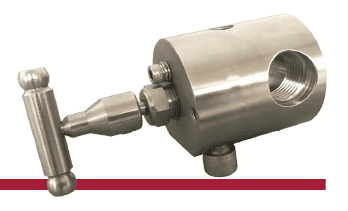

Models: SMPSVSBBSS

Max Working Pressure: 3000 psi @100 F

Max Design Temp: 400 F @1500 PSIG - PTFE

Flow Path Orifice: 0.70"

Sample Orifice: 0.125"

Body: 316SS / M-400 / HC-276

Seats: Ceramic

Key Features:

· Designed Specifically for Grab Sampling Industry

· Eliminates Dead Volume

· Packing below the threads prevents media from coming in contact with the threads of the stem

· Available in various metallurgies to ensure compatibility with virtually any low vapor pressure Liquid

· The unique flow-thru design ensures no process flow path restrictions

· The rising stem allows for better pressure and flows control of media into the sample bottle

Datasheet

Ready to find out more?

Drop us a line today for a free quote!

Inline Sampling Systems

Models: ISS

Warranty: 1 Year

Available in wide variety of piping materials and end connections

Suitable for high temperature, high viscosity service

Available with open tube “stinger” or process needle

The SENSOR Inline Grab Sampling System (ISS) fits into a piping system without the need to utilize, or create, a pressure differential fast loop to take a sample. It can be designed to fit into virtually any diameter piping system and any flange configuration. The ISS uses a special long-body needle valve and can also be configured with a collection chamber.

SENSOR welds a specially designed sample valve into a spool piece matching your piping specification. The valve body can be fully purged to ensure zero dead volume by residual elimination. This purge eliminates any potential plugging issues and ensures process media is not vapor locked in dispense tube.

Typical applications for the SENSOR ISS include hot oil, refinery “bottoms”, and resid oil. Our robust valve is fitted with graphoil packing for high temperature applications. We heat trace any exposed areas to maintain adequate process temperature to allow for a freely flowing sample. We enclose the valve and sample receptacle in a specially designed enclosure which can be fitted with an optional educator to exhaust harmful vapors to a safe location.

- Can be provided in virtually any material to match the piping system in which it is installed

- Available with collection chamber, model PIISS

- Optional SENSOR Sampling CONCENTRIC single needle design is available

- Operating Instruction Manual included

Be sure and look at the other sampling system models that are available like the RAM Sampling Systems

Datasheet

Ready to find out more?

Drop us a line today for a free quote!

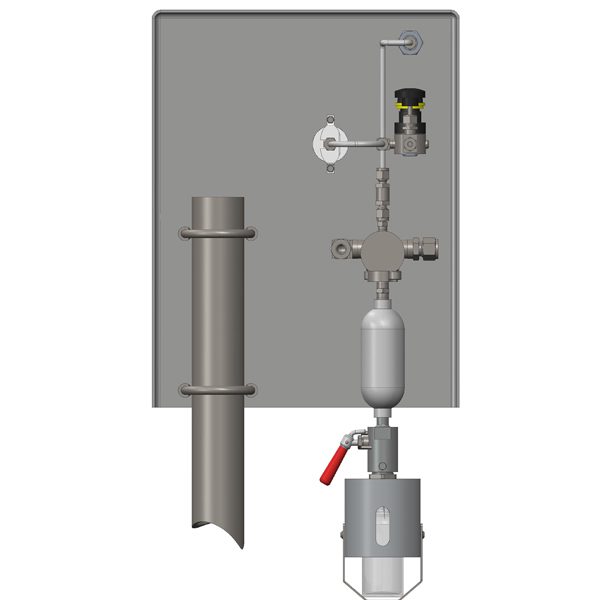

Pressure Isolating Bottle Sampling Systems

Models: PIBSS

Warranty: 1 Year

Guarantees repeatable sample volume

Zero dead volume

Replaceable process and vent needles

Suitable for high process pressures

SENSOR Needle Evacuation System standard

Eliminates over filling of sample container

The SENSOR Pressure Isolating Bottle Sampling System (PIBSS) provides a repeatable volume of sample during each sampling process without stopping flow of the process fast loop. As a safety precaution, it helps prevent overfilling of bottle. It utilizes the same sample valve as the Basic Bottle Sampling System (BBSS), with the addition of a needle valve to control the flow of the isolated sample into the sample bottle. No external tubing is required for the collection vessel chamber. The collection vessel chamber will be sized to meet the exact requirements of your sampling application. PIBSS is recommended when process pressure exceeds 150 psig or when a repeatable, defined volume of sample is desired. SENSOR Needle Evacuation System (NES) is included in the fixed volume design.

- Closed loop design with captured vent ensures zero emission

- Eliminate the possibility of overfilling a sample bottle

- Automatically purges process needle of any residual process thru SENSOR Needle Evacuation System (NES) which ensures residual elimination between samples

- Optional SENSOR Sampling CONCENTRIC single needle design is available

- Positive indication of free-flowing system; no plugged sample or vent needles

- Isolates sample bottle from process pressure

- 316L wetted parts standard

- Viton/Teflon seals standard

- Standard shroud sizes are 2 oz. to 32 oz. (60mL – 1000mL), other sizes available upon request

- Operating Instruction Manual included

Be sure and look at the other sampling system models that are available like the RAM Sampling Systems.

Datasheet

Ready to find out more?

Drop us a line today for a free quote!

This group of process liquids has a vapor pressure < 19 psia and will not generally vaporize under normal atmospheric conditions. Samples in this group are caught in bottles with a cap and septum sealing system used to capture venting and eliminate spilling of the sample during transport to the lab. The sample valve design provides for excellent flow control during filling, reducing the potential of operator or environmental exposure.

under normal atmospheric conditions. Samples in this group are caught in bottles with a cap and septum sealing system used to capture venting and eliminate spilling of the sample during transport to the lab. The sample valve design provides for excellent flow control during filling, reducing the potential of operator or environmental exposure.

The SENSOR Basic Bottle Sampling System (BBSS), is a closed loop sampling system utilizing a unique flow-thru valve design that simplifies the sampling process by eliminating additional operations in order to grab a sample. The design allows for sample collection, venting and nitrogen purge within the interior of the sample valve. The valve design allows for virtually NO dead volume when used in conjunction with the SENSOR Needle Evacuation System (NES) option.

For process pressures > 175 psig the SENSOR Pressure Isolating Bottle Sampling System (PIBSS) is perfect for handling hazards that tend to compound with increased operating pressures. The sampling system PIBSS is designed to isolate the operator from the process pressure, while blowing the sample into the bottle at N2 purge pressure, usually set to 6 psig.

These closed loop sampling system types can be used to sample a wide variety of chemicals and petrochemicals where there is concern for personnel exposure and environmental impact. Sampling components can be fabricated from 316L SS, Hastelloy C276, Monel and other similar types of materials.

Key Features

- Designed for placement into fast loop to ensure fresh representative sample is always present

- Flow-thru sample valve design to reduce dead volume, plugging and sample contamination

- Versatile, multifunctional design allows for a variety of sampling techniques with common components

- Sample valve stem threads are located above the valve packing to provide long-lasting and reliable operation

- Sample valve utilizes a metal seat and a floating ceramic ball design for sealing

- Components are panel mounted on 11gauge 304 SS plate to prevent warping and process leakage

- Operating Instruction Manual included

- Standard Design Conditions up to 2,000 psig and 800oF maximum with cooler and Graphoil packing

Industries Served

- Refining

- Petrochemicals

- Chemicals

- Specialty Chemicals