Heavy Products Sampling Systems

Ready to find out more?

Drop us a line today for a free quote!

Datasheet

Models: HPSS

Warranty: 1 Year

Non-insulated sampling system enclosure to prevent splashing and burns

Steam purge sample path independent of process flow to prevent plugging

Removable/replaceable cartridge system to allow repair or replacement without removing the valve base and pipe spool

Twist Lock Purge Adapter to contain and direct all purged residual to enclosure drain

Unique 3-way valve ensures steam is kept hot and condensate free

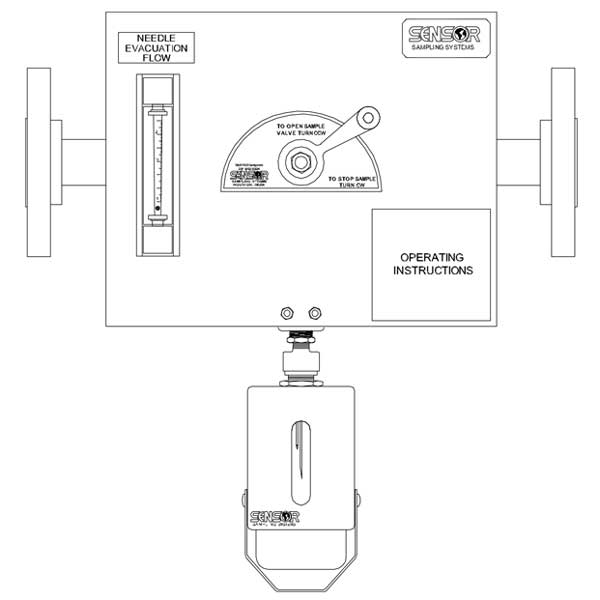

The SENSOR Heavy Products Sample System (HPSS) is designed to collect samples of hot, heavy products (such as resid, asphalt, hot tar, gas oil, resins, slurries, surfactants and emulsions) while maintaining personnel safety.

Sample Heavy Products with Minimal Downtime

The HPSS comes with 3 standard features unique to SENSOR which include a removable cartridge valve, condensate-free steam flush assembly and twist lock purge adapter.

Removable Cartridge Valve. Allows for separating the valve’s critical components from the sample line without removing the valve body and pipe spool from the process line in the event of required maintenance. The cartridge can simply be removed from the sample valve base and repaired or replaced with a new one, greatly reducing downtime.

Condensate-free Steam Flush Assembly. This assembly utilizes a unique 3-way valve and steam trap to ensure that condensate-free steam is consistently available for purge operations. The steam purge clears any potential blockage from the sample path without disrupting the process flowing in the sample line.

Twist Lock Purge Adapter. Without the need for tools, an operator can easily install the twist lock purge adapter onto the dispense tube and utilize steam to completely flush out the sample pathway to the drain of the enclosure. The steam flush is directed in a controlled manner without creating a mess on the inside of the enclosure or window from splatter.

- Safe collection of hot liquid without exposure to the operator

- High Viscosity “HV” Sample Valve allows the operator to control the rate of flow into the container

- Sample Valve includes a “Cartridge Design” that allows it to be changed quickly without removing the entire Flanged Spool Assembly

- Sample Valve has increased port size over the typical BBSS valve to handle heavier products

- Steam Heated Dispense Tube ensures that any residual that remains in the dispense tube (due to vapor lock when the sample valve is closed) remains hot and fluidized until it can be purged out

- Steam Purge after each sample collection ensures the sample valve and dispense tube are fully cleaned out after each use eliminating the chance of plugging

- Steam Supply is kept hot and condensate- free with the use of a unique 3-way Needle Valve and Steam Trap

- Twist Lock Purge Adapter ensures that all residual material that is purged out is contained and pushed down the metal flex hose to the drain of the enclosure instead of spraying out inside of the enclosure

RAM Sampling Systems

Models: RSS

Warranty: 1 Year

Available in wide variety of piping materials and end connections

Suitable for high temperature, high viscosity service

Can be provided with a variety of connections to attach to existing piping or vessels

Available with open tube “stinger” or process needle

The SENSOR RAM Sample System (RSS) is designed to attach directly to the side of a tank or pipeline without the need to utilize, or create, a pressure differential to take a sample. The RSS uses a Piston Type Ram Sample Valve which works very well in high viscosity or high particulate applications which are prone to plugging. As the valve is rotated the piston draws back and allows the liquid to flow through to the sample port. When the Piston Ram Valve is rotated to close, it pushes back any remaining product to ensure no cross contamination between samples and zero dead volume.

SENSOR RAM Sample System can be supplied with a flanged, threaded, or welded connection to mate up to existing piping. It can also be supplied with a piping spool to fit into an existing pipe line with either a threaded or flanged type of connection. The RAM Valve can be fully purged with use of a purge adapter to eliminate any dead volume below the valve and eliminate potential plugging issues.

Typical Applications for the SENSOR RSS include hot oil, refinery “bottoms”, hot asphalt, resid oil, and any other low vapor pressure hydrocarbons where a fast loop is not present or easily achievable. The RAM Sample valve can be fitted with Teflon® or Graphoil packing to meet the requirements of most applications. We can heat trace any exposed areas to maintain adequate process temperature to ensure a free flowing sample. We can enclose the Ram Sample Valve and sample receptacle in a specially designed enclosure for operator protection while sampling. The enclosure can also be fitted with an optional eductor to exhaust harmful vapors and smoke to a safe location if open top container sampling is preferred.

- Can be provided in virtually any material to match the piping system in which it is installed

- Can be provided with a variety of connections to attach to existing piping or vessels

- Available with collection chamber, model PIRSS

- Optional SENSOR Sampling CONCENTRIC single needle design is available

- Operating Instruction Manual included

Be sure and look at the other sampling system models that are available like the Cylinder Sampling Systems

Datasheet

Ready to find out more?

Drop us a line today for a free quote!

This group of process liquids has a vapor pressure < 19 psia and have high viscosities with the potential to turn to solids at ambient temperatures. This group of heavy liquids are typically caught in metal open top containers due to the high operating temperatures. With a desire to keep the sample hot to avoid plugging, the sample is typically collected in an enclosure to avoid splashing and potential for burns to the operator. Once the sample is collected it is often allowed to cool before transportation to the laboratory.

The SENSOR Heavy Products Sampling System (HPSS) utilizes a similar flow-thru design to the BBSS unit allowing for flow control of the product as it enters the sample container. With the use of large front and top window in the enclosure the operator can get a good view as the sample enters the container. The twist lock purge adapter along with the 3-way steam valve ensures that steam is condensate free to be used to clean out the HPSS unit after each use. Proper cleaning ensures that the HPSS unit is ready and available for each use for quite a difficult group of applications.

Typical SENSOR HPSS applications would include; residuum (Resid), asphaltenes, hot tar, condensate, bitumen, vacuum tower bottoms, reformate and many other chemical compounds.

The SENSOR RAM Sample System (RSS) is designed to attach directly to the side of a tank or pipeline without the need to utilize, or create, a pressure differential to take a sample. The RSS uses a Piston Type Ram Sample Valve which works very well in high viscosity or high particulate applications which are prone to plugging. As the valve is rotated the piston draws back and allows the liquid to flow through to the sample port. When the Piston Ram Valve is rotated to close, it pushes back any remaining product to ensure no cross contamination between samples and zero dead volume.

Typical SENSOR RSS applications would include; amines, benzene, ethylene di-chloride (EDC), hydrochloric acid (HCl), sulfuric acid, hydrotreating, gas oils, naptha, sour water, caustic, residuum (Resid), asphaltenes, hot tar, condensate, vacuum tower bottoms, reformate and many other chemical compounds.

Key Features

- Designed for placement into fast loop or process piping to ensure fresh representative sample is always present

- Flow-thru sample valve design to reduce dead volume, plugging and sample contamination

- Removable/Replaceable cartridge to allow repair or replacement without removing valve base and pipe spool

- Versatile, multifunctional design allows for a variety of sampling techniques with common components

- Sample valve stem threads are located above the valve packing to provide long-lasting and reliable operation

- Sample valve utilizes a metal seat and a floating ceramic ball design for sealing

- Operating Instruction Manual included

- Standard Design Conditions up to 2,000 psig and 800oF maximum with Graphoil packing

- Design of sample path allows for full sweep of steam or solvent flush when required

- Over filling of sample container is minimized with excellent flow control with multiturn rising stem design

- Piston/Ram valve design minimizes dead volume when direct mounting to the process nozzle is required

Industries Served

Refining

Petrochemicals

Chemicals

Specialty Chemicals